Why are pollution control and enhanced safety vital factors during small animals’ gas anesthesia?

- Emma Danciu

- Apr 4, 2025

- 4 min read

Updated: Apr 7, 2025

In today’s world where everything revolves around energy saving, environment protection, and health safety, pollution control and enhanced safety are a significant concern for the user during rodents’ gas anesthetic protocols.

Because of the use of anesthetic gases, such as isoflurane or sevoflurane, commonly implemented with anesthetic devices, and the fact that recommended exposure levels vary by country, it is essential to become aware of the associated health and safety risks for users.

Even though isoflurane is preferred because it induces and wears off quickly, has minimal effects on brain blood flow auto-regulation, heart function, and on the body’s overall metabolic activity, it is crucial to understand that exposure to high concentrations of waste anesthetic gas (WAG) can lead to various adverse health effects, including headache, irritability, fatigue, cough, sore throat, nausea, drowsiness, impaired judgment and coordination, as well as cancer, liver and kidney disease.

Despite the fact that the National Institute for Occupational Safety and Health (NIOSH) recommends keeping the operator’s exposure limit to anesthetic gases to 2ppm as an average over a 60-minute period (compared to Europe where the standard is 2ppm over an 8-hour period!), it is rarely enforced.

With manually controlled devices, due to the lack of active vacuum, small amounts of waste anesthetic gas (WAG) often leak into the air during the anesthesia administration and endanger the user’s health.

First, with the use of a flowmeter the amount of gas administered in the vaporizer is inherently approximate because selecting the appropriate gas flow using the float often results in a margin of error, which can significantly affect both the user's safety and the animal's comfort.

Also, the gas distribution system connected to the mask(s), which operates through tube(s) and valve(s), poses a risk of gas intoxication. If the valve is opened before the rodent’s muzzle is properly secured in the mask, the gas leaks into the air.

Second, many manually operated workstations lack a scavenging system. As a result, once the gas is injected into the induction chamber (or the mask) and the animal (rodents like rats or mice) is anesthetized, the operator opens the chamber to remove the animal. This action allows a significant concentration and volume of gas to escape simultaneously, definitely exposing them to gas emanations.

Third, an active scavenging system, which not all anesthesia devices are necessarily equipped with, utilizes electric WAG extraction using charcoal canisters. Failure to replace these canisters can lead to gas intoxication.

The challenge lies in assessing when a new canister is required, as this determination is based on weighing it. Frequently, the weight is not documented, resulting in the user being unaware of its ineffectiveness, thereby exposing them again to gas emissions.

At TEM SEGA USA, one of our priorities is to be aware of the user’s health risk and the animal’s welfare, ensuring appropriate handling and taking necessary actions.

This commitment has led us to develop the most advanced gas anesthesia stations on the market, offering unparalleled features to securely and effectively manage anesthetic protocols.

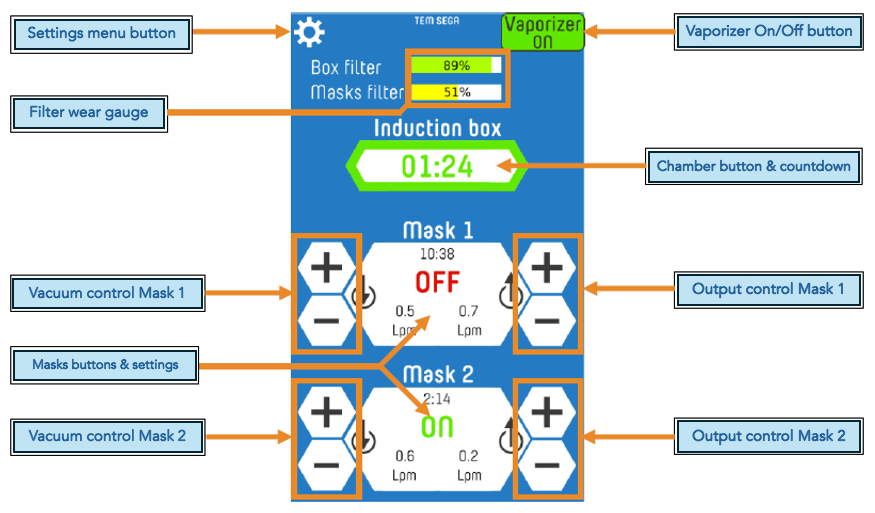

Our automated gas anesthesia stations, the MiniHUB V3 and the NanoHUB are compact and portable. They are all-in-one stations displaying secure settings drastically reducing the margin of error.

Our stations incorporate unique automated parameters throughout, from setting the exact amount and percentage of gas needed to be delivered for one or several induction chambers/masks, to determining the time for the animal to be anesthetized, and from removing the animal from the induction chamber, placing a mask on it and keeping the anesthesia going, to accurately controlling the scavenging system.

These features are powerful assets to pollution control and enhanced safety during rodents' gas anesthesia.

First, whether the operator is using the induction chamber(s) or the mask(s), the vaporizer’s gas flow AND percentage are precisely controlled through the touch screen, ensuring that the risk of endangering the user’s health is close to none, as well as maintaining the animal’s well-being. There is no flowmeter here delivering an approximate amount of gas.

With respect to the release of gas to the mask(s) using our stations, there is an automatic detection feature that determines when to activate and disable the inlet and suction flows. Our stations automatically detect whether the mask is positioned on the muzzle of the rats or mice. This ensures that there is no risk of gas leakage into the environment.

Second, our uniquely designed induction chamber offers the ONLY feature on the market preventing from ANY GAS to escape from it with its SAFETY SYSTEM.

By opening the lid and pressing onto the inlet, the incoming gas automatically and instantly stops coming into the chamber, while activating the scavenging system. The induction chamber features a powerful gas suction capacity of 18L/min, avoiding any exposure to the user.

Third, regarding the scavenging system, the charcoal canisters are link to the user interface, therefore, the outlet flow is securely incremented or decremented by 0.1 L per minute. Also, the life expectancy of the canister being automatically detected, the user knows exactly when it is time to replace it.

Through the diligent work of our Research and Development team, we aim for our gas anesthesia stations to redefine the user experience and animal comfort by incorporating pollution control and enhanced safety, vital factors during small animals' gas anesthesia..

Being automatically regulated and equipped with unique functionalities, they provide, not only the most intuitive and effective use, but also ensure a safe working environment while limiting health risks to a minimum.

Comments